arenared’s delivery package:

- electronic control unit with ar-cpbc-chip

- combustion pressure sensor (cps), automotive, fiber optical

- fuel injectors, with integrated tip cooling, double wall, integrated cps

- with rcci 1% diesel is injected 100% before top dead centre (tdc), resulting in ignition in the gas stage instead of ignition in the flued stage like today diesel only.

- rcci results in 10%+ better fuel economy than diesel only

- tier iv final, stage-v and euro-6D without scr urea

- cheaper production of entire engine due to the possibility to allow lower tolerances of compression ratio and injectors

- enabling bio based economy: all fuels become possible, like hydrogen, biogas, methanol and ethanol in the diesel engine.

- fuels in random mix from 1 tank

arenared designs, sources out and delivers:

- ar-ecu with injector drivers, obd, canbus

- chip for combustion pressure based control

- fiber optical combustion pressure sensor (cps)

- diesel injector with integrated cps

- double wall gas safe maritime class approved gas injector

- total solutions

want more information?

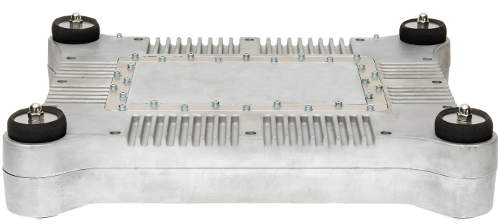

ECU - ELECTRONIC CONTROL UNITS

the cpbc diagnostics used for optimizing the combustion process and protecting the engine are extracted from every cylinder and used as feedback in closed loop control for the actuators like diesel and gas injectors. therefore the ecu requires a substantial amount of computing power to process the data coming from the cps. this is delivered by the arenared cpbc chip. combustion concepts like rcci are unstable and can only be run stable by using cpbc with high speed feedback. the arenared chip is able to run more than 1000 cpbc processes in parallel. the arenared cpbc chip provides an enormous amount of control possibilities. this makes it possible to integrate functionalities from other devices, when saving a controller is desired to reduce cost. integrations could be:

control of

- alternative fuel supply

- severe communication and even control if desired in hybrid applications

- gearbox

- waste heat recovery

- trip planning

- regulating cooling engine

- valve timing

- in case the ultra lo emission of particle matter with arenared rcci 3 times under euro-6D is desired to bring back to zero, meaning 5.000.000 particles per m3 less than the air we breathe. a robust partical filter could be applied and the regeneration than can be controlled by arenared’s cpbc chip

ECU - THE ELECTRONIC CONTROL UNIT PACKAGE

in order to provide demonstrations for new or other customers, the ecu is built as an engine laboratory tool. it has 16 peak hold injector drivers and is capable to drive any kind of injector, solenoid or piezo injector. the ecu is fitted with extra in- and outputs for additional peripherals. the ecu can also be used as an engine data acquisition system.

specs ecu hardware

- ar-chip that can handle the sample rate and processing power required for cpbc

- capable of engine speeds up to 22.000 rpm

- 16 injector drivers to a maximum of 250 volt peak, INDIVIDUALLY OPTIMISED FOR LOW VARIATIONS BETWEEN INJECTIONS AND HIGH ACCURACY AT LOW INJECTION VOLUMES

- 8 can busses

- 1 giga bit ethernet

- 32 digital inputs

- 54 a/d converters

- 2 vr sensor reed in

- 1 hall sensor reed in

- 2 rotary encoders

- 2 full duplex rs485

- 1 cascade interface

specs ecu software

the engine software is written in matlab/simulink with a shell of c#. the arenared cpbc chip provides all required, such as:

- parameters to optimize efficiency, emissions and lifetime.

- ca50, ca10 and ca90, for analyzing combustion phasing

- indicated mean effective pressure (imep), for analyzing the load and for balancing the injectors

- cycle temperature, for analyzing the emissions production

- combustion diagostics to prevent engine damage

- canbus, j1939 communication with all other periphery apparatus

- on board diagnostics (obd)

- all diagnostics which are standard available on the cat 3500 plus all diagnostics coming from the cpbc

CHIP

the arenared cpbc chip can be customized and delivered as a product on its own.

arenared’s software can be bought as a single product on its own.

CPS - COMBUSTION PRESSURE SENSORS

arenared’s combustion pressure sensor (cps) is a fiber optical sensor that measures the light intensity reflected by a membrane exposed to the pressure. the uniquely designed fixation of the fibers and heat conductivity of the sensor membrane and body ensures the exceptional durability, even with (undesirable) knocking events and even with constant heavy knocking. commonly used fiber optical sensors require a heatshield that in time clog with soot and cause a sensor fail. because of the unique design the arenared cps does not require a heat shield for protecting the sensor.

a drawback of the fiber optical sensor especially without a heat shield, is that the membrane becomes hotter on the outside than on the inside, the thermal expansion of the outside of the membrane causes a displacement of the membrane that will be seen as an pressure change, which is known as thermal shock error. the arenared cps therefore has two locations to measure the displacement of the membrane and this way arenared is able to eliminate the thermal shock error. this double measurement is patented by arenared. using the double measurement, the arenared cps gives information about the combustion temperature as well, which can be used to optimize engine efficiency by reducing heat loss.

beside the combustion temperature delivered from the arenared cps, the combustion temperature is also derived from the combustion pressure and the cylinder volume. this is a major arenared control strategy and also patented by arenared. the emissions are optimized by keeping the combustion temperature below the thermal nox formation temperature and above the ch4 oxidation limit (patented by arenared).

- the cps electronics give a canbus diagnostics readout.

- the power feed can be in the range of 5 to 32 volt.

- the signals are supplied as 4-20 mamp or 0,5 to 4,5 volt.

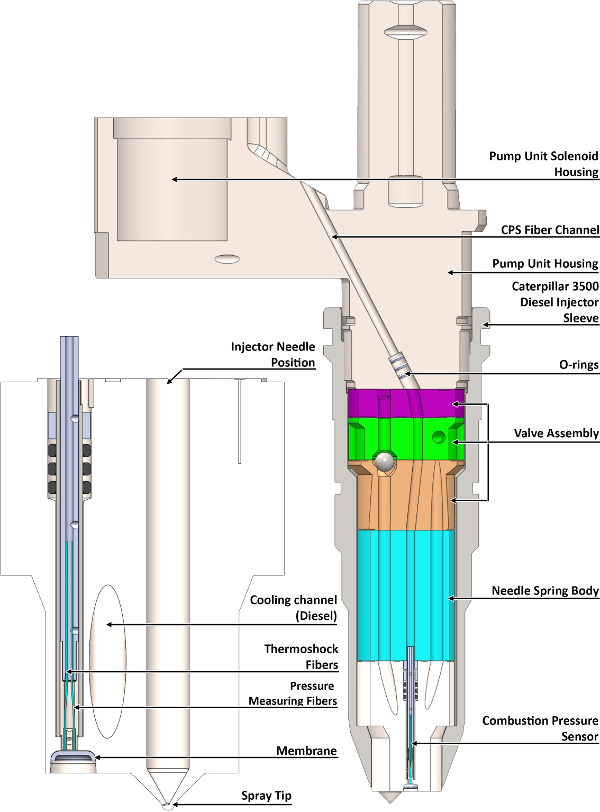

CPS INTEGRATED IN DIESEL INJECTOR

the arenared docat 3500ar cps has the same membrane and electronics as the m5 version. the fibers are placed in a separate unit which is in the arenared nozzle in the injector. arenared is able to produce diesel nozzles with an eccentric placed needle, which makes it possible to integrate the sensor within small diesel injectors used in the smallest personal cars.

the arenared fiber optical combustion pressure sensor can be built in any diesel injector, gas injector or glowplug.

CPS M5

the arenared fiber optical combustion pressure sensor is deliverable as a m5 x 0,5 body.

DIESEL INJECTOR WITH TIP COOLING AND CPS

the diesel injectors for the docat 3500ar retrofit package are designed by arenared and produced in the netherlands under arenared’s supervision by specialized dutch production companies.

special features of the patented arenared diesel electronical unit injector (eui) are:

- tip cooling (patented). the entire volume of the eui pump stroke is pumped through the nose of the nozzle, this reduces the temperature of the diesel at the needle.

- parallel needle micropilot (patented). this small diesel injector or micropilot enables us to accurately inject small diesel quantities with little variation from stroke to stroke.

- parallel needle main diesel injector. the main injector is used for running at 100% diesel mode.

- the main is actuated by the same solenoid as the micropilot. the injection duration determines if the main injector opens.

- combustion pressure sensor (cps) integrated in the injector (patented) which prevents drilling in the cylinder head for placing the cps.

due to new production methods arenared is able to produce:

- asymmetric diesel nozzles and diesel injectors

- parallel needle diesel nozzles

- concentric needle and needle in needle diesel nozzles

- large engine nozzles

- small engine nozzles

- diesel injector parts

- low volume

- high volume fully automated

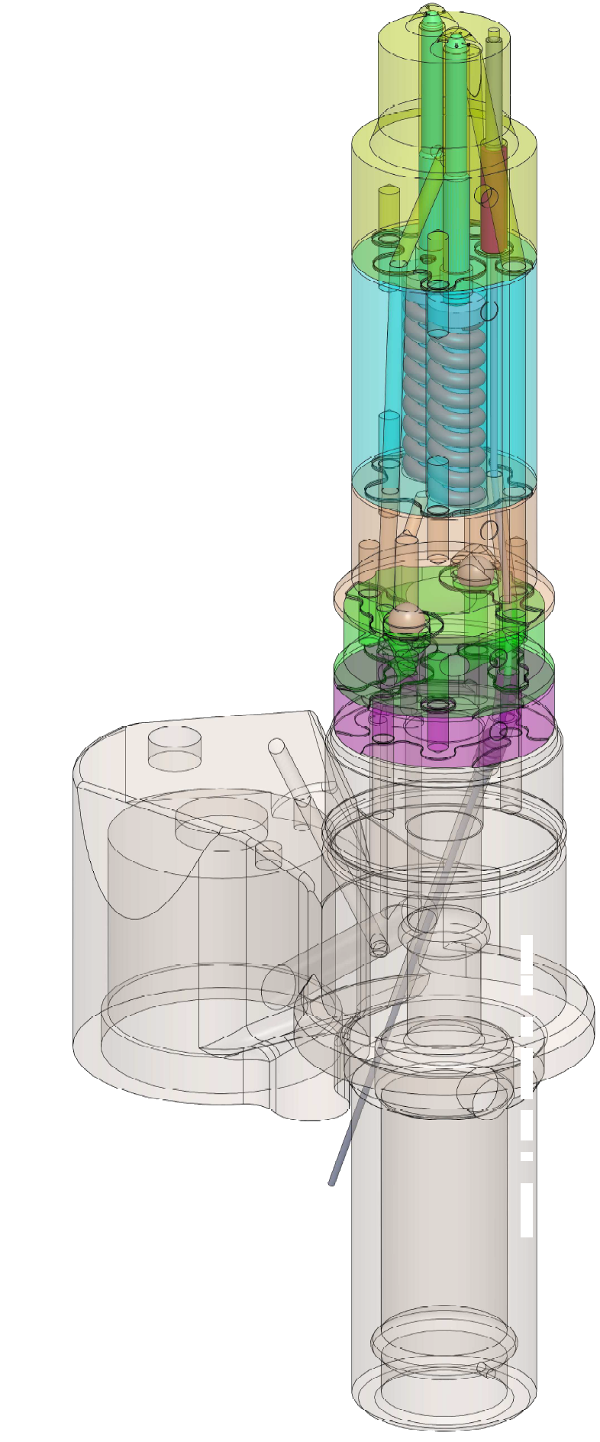

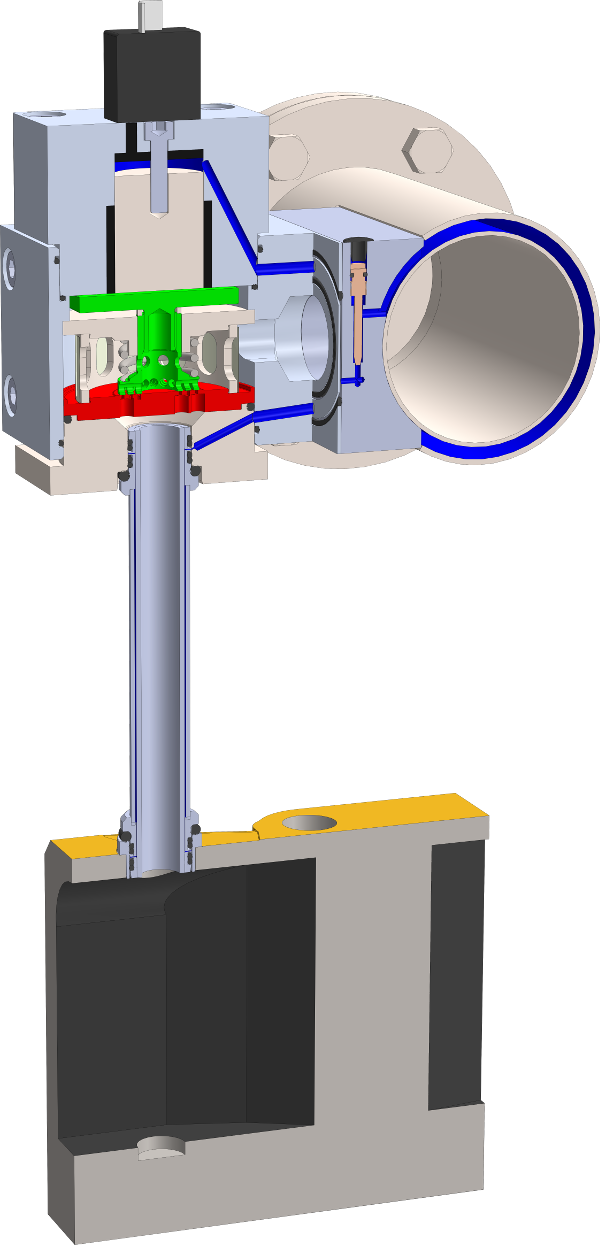

DOUBLE WALL GAS INJECTOR

the double wall arenared gas injector is lloyds approved and can be supplied as oem or retrofit package which prevents the need for extra ventilation in the engine room. the double walled lloyds gas safe approved gas injector is patented.

design specifications gas injector:

- lloyds approved double walled gas safe

- 30 mu gas filter inside

- steel on steel seal

- 330mm2 throughput

- 0,6mm valve lift

- maximum pressure difference between rail and manifold of 4 bar

- maximum back pressure from manifold of 6 bar

- time to open < 3ms

- time to close < 3ms

- solenoid < 118 volt needed for peak

ENGINE LAB

arenared’s ecu is developed to act as an engine lab data acquisition system. there are analog in- and outputs reserved for connecting additional research sensors and actuators.

with the arenared ecu you can turn every cylinder into an individual engine research lab to be used for research or educational purposes. through the software which is especially designed for research you have full control over all the control parameters.